ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

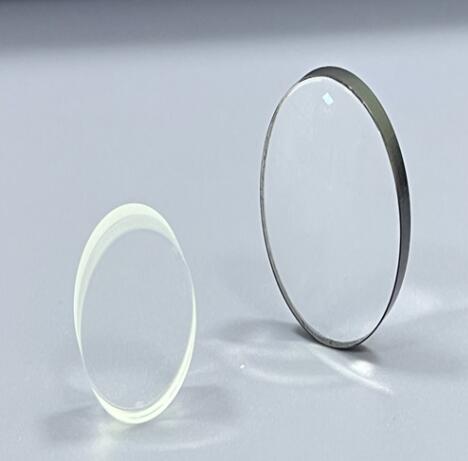

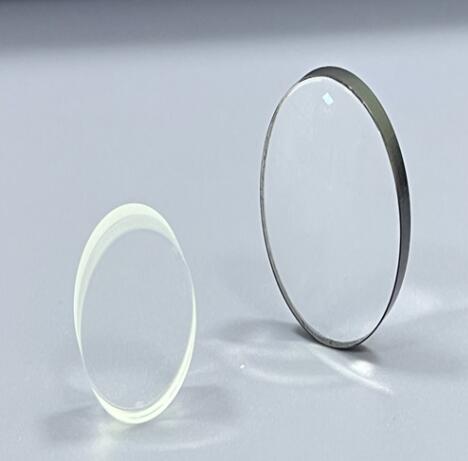

Method of manufacturing glass lenses

1, the previous method: the melted optical glass in the moulding process to make the diameter and the diameter of the lens to be processed slightly larger glass rods, and then cut into sheets according to the thickness of the lens. Take to the specialised mechanical processing instruments, according to the requirements of processing into finished products. The process of processing is mainly: rough grinding, medium grinding, fine grinding, fine grinding, polishing, annealing. The materials used for rough grinding to fine grinding are mainly various kinds of diamond sand with different grain sizes. The method of polishing, in case of low requirements, can be flame polishing. Advanced lenses must use mechanical methods, the polishing material is generally cerium oxide. 2, the current method is to first use the mould hot pressing forming. The main purpose is to reduce the waste brought by processing in the original method as well as to improve the working efficiency. The method is: according to the quality of the lens to determine the quality of the molten state of the glass, the glass at a certain temperature, viscous state of the glass into the mould, press forming, and finally annealed. The result is one of two things: firstly, the moulded product can meet the requirement of dimensional accuracy in one go. Very minor defects can be compensated by coating. The requirements for moulds are very high, and as far as I know they are not available in China at present. This kind of product can meet most of the needs. The precision of the lens is mainly affected by the precision of the mould. Secondly, the moulded products are blanks with high precision, and then machined according to the original method mentioned above, but the processing quantity is very small, which can obviously improve the production efficiency. This method is mostly adopted for products requiring very high precision. The precision of the lens is mainly affected by the precision of the machining instrument.

PREV : coating manufacturing methods NEXT : Basics of Coating

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388