ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

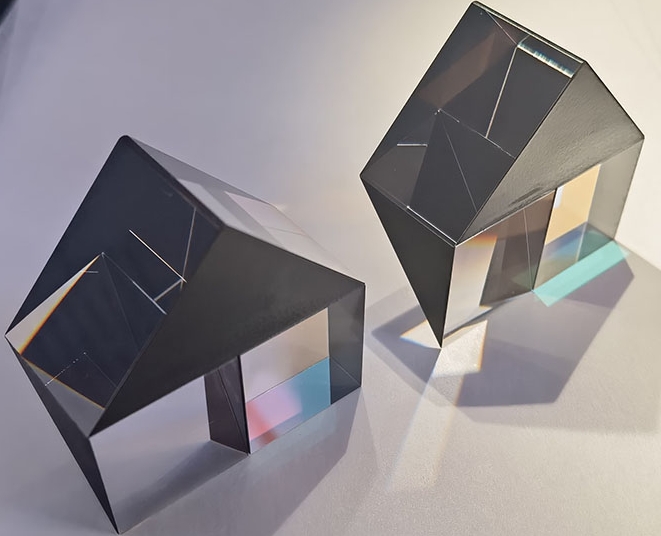

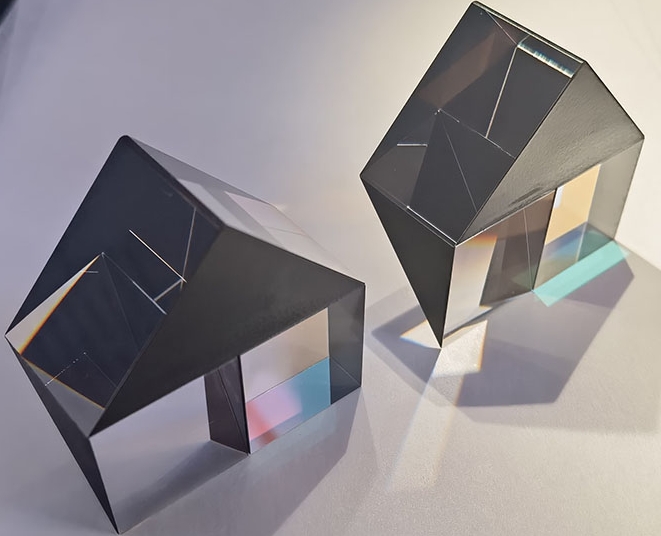

Glue Prism Process

Optical prism gluing process is one of the processing methods in the optical component bonding process (the other two bonding processes are: mechanical method, optical glue method). The gluing of optical prisms is mainly to allow optical components to improve the image quality of the optical system, reduce the loss of light energy, increase the clarity of the image, the protection of the scale surface, and further optimise the processing process to meet the design requirements. The gluing of optical prisms is mainly done with the use of optical industry standard adhesives (colourless and transparent, with a transmittance rate of more than 90% in the specified optical range). Optical bonding is carried out on the surface of the optical glass. Optical prisms to ensure that the optical properties and mechanical properties of the optical parts obtained by gluing prism gluing UV glue features: 1. colorless, high transparency; no bubbles, no watermarks and oil mist, etc. 2. high bonding strength, adhesive layer is firm, no internal stress. 3. temperature, humidity resistance is good, there is enough stability. 4. gluing shrinkage is small, to ensure that the centre of the glued lens error, to ensure that the glued pieces of the face type Precision. Widely used in military, aerospace and industrial optics for bonding lenses, prisms, mirrors and terminating or splicing optical fibres. Complies with MIL-A-3920 for optical bonding materials. The gluing process of optical parts refers to the process of bonding two or more lenses, prisms, mirrors, and optical surfaces that coincide with each other into optical parts by means of optical glue or optical adhesive in accordance with certain technical requirements. In actual production, gluing has two technical requirements; one is to ensure that the centre of error or angular error, for the lens, to ensure that the centre of chromium lens error: for prisms or plane mirrors, to ensure that the optical parallelism of the prism. One is to ensure that the glued surface to achieve "zero defects" gluing, that is, to ensure that the glued polished surface is not glued to reduce the requirements of the surface coagulation, and not because of the gluing and the impact of non-glued surface of the surface shape.

PREV : Uses of Silicon Lenses NEXT : Infrared silicon lens

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388